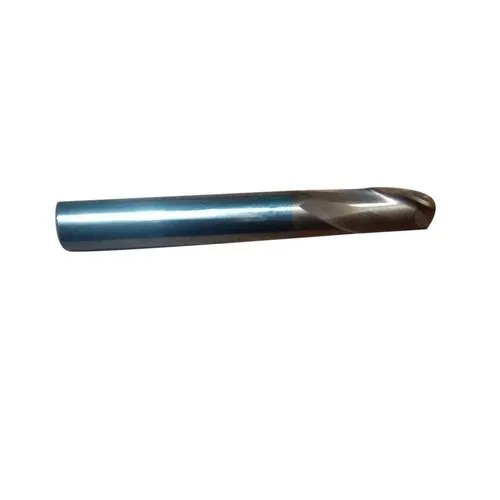

300mm Carbide Ball Nose End Mill Cutter

Price 500 INR/ Piece

MOQ : 50 Pieces

300mm Carbide Ball Nose End Mill Cutter Specification

- Length

- 300 Millimeter (mm)

- Features

- Good Quality

- Hardness

- 70 HRC

- Usage

- Industrial

- Material

- Stainless Steel

- Operate Method

- Manual

- Operation Type

- Finishing

- Product Type

- Carbide Ball Nose End Mill Cutter

- Color

- Silver

300mm Carbide Ball Nose End Mill Cutter Trade Information

- Minimum Order Quantity

- 50 Pieces

- Supply Ability

- 1000 Pieces Per Month

- Delivery Time

- 7 Days

About 300mm Carbide Ball Nose End Mill Cutter

Discover the fresh, outstanding performance of the 300mm Carbide Ball Nose End Mill Cutter-crafted from noble stainless steel and boasting inestimable value for industrial finishing operations. With its hard 70 HRC edge, this silver beauty ensures good quality and longevity. As a hot deal from a reputed supplier and trader in India, avail instant checkout to secure your machine tool today. The manual operate method gives users precise control, delivering a product that's truly inestimable both in reliability and efficiency.

Exceptional Features and Versatile Application

The 300mm Carbide Ball Nose End Mill Cutter stands out for its robust 70 HRC hardness and high-quality carbide construction, ensuring enduring performance in demanding industrial environments. Designed for finishing operations, its manual operation offers versatility and precise control. Suitable for machine shops, manufacturing plants, and factories, this cutter's advantages are reflected in its durability and outstanding machining ability, making it the preferred choice for professionals seeking quality results.

Extensive Market Reach and Efficient Delivery

This ball nose cutter captures significant market value, shipped extensively across India and global export markets. Its competitive outlay ensures buyers receive inestimable worth for their investment. Our instant checkout process expedites order placement, allowing prompt shipment and timely delivery. Customers across major domestic regions and international sectors can depend on reliable logistics to receive their machines quickly, maximizing productivity with minimum delay.

Exceptional Features and Versatile Application

The 300mm Carbide Ball Nose End Mill Cutter stands out for its robust 70 HRC hardness and high-quality carbide construction, ensuring enduring performance in demanding industrial environments. Designed for finishing operations, its manual operation offers versatility and precise control. Suitable for machine shops, manufacturing plants, and factories, this cutter's advantages are reflected in its durability and outstanding machining ability, making it the preferred choice for professionals seeking quality results.

Extensive Market Reach and Efficient Delivery

This ball nose cutter captures significant market value, shipped extensively across India and global export markets. Its competitive outlay ensures buyers receive inestimable worth for their investment. Our instant checkout process expedites order placement, allowing prompt shipment and timely delivery. Customers across major domestic regions and international sectors can depend on reliable logistics to receive their machines quickly, maximizing productivity with minimum delay.

| Cutting Diameter(D1) | 10 mm |

| Maximum Cutting Depth | 5 mm |

| Overall Length | 300 mm |

| Length Of Cut | 10 mm |

| Material | Carbide |

| Helix Angle | 90 Degree |

FAQ's of 300mm Carbide Ball Nose End Mill Cutter:

Q: How is the 300mm Carbide Ball Nose End Mill Cutter typically used in industrial finishing?

A: It is primarily employed for precision finishing operations on metalwork, producing smooth, contoured surfaces and intricate profiles in industrial settings.Q: What distinguishes the cutter's quality from other available options?

A: The cutter's outstanding 70 HRC hardness and use of stainless steel make it remarkably durable and effective, ensuring excellent results for extended periods.Q: When can customers expect delivery after placing an instant checkout order?

A: Orders are shipped promptly after purchase, with delivery times varying depending on location but typically completed within standard business timelines.Q: Where is this cutter mainly supplied and traded?

A: It is supplied and traded throughout India's main domestic markets and exported to major international industrial sectors.Q: What is the process for operating this tool manually?

A: Operators manually mount the cutter, align it accurately, and guide it through the finishing process on machining equipment for optimal precision.Q: What advantages does the carbide construction provide during use?

A: The carbide ball nose design improves longevity, maintains surface finish quality, and withstands intensive industrial stresses without premature wear.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Ball Nose Cutter Category

Carbide End Mill Ball Nose Cutter

Price 499 INR / Piece

Minimum Order Quantity : 50 Pieces

Product Type : Carbide End Mill Ball Nose Cutter

Coating : Polished

Length : 100 Millimeter (mm)

Material : Stainless Steel

10mm Carbide Ball Nose Cutter

Price 80 INR / Piece

Minimum Order Quantity : 100 Pieces

Product Type : Carbide Ball Nose Cutter

Coating : Polished

Length : 200 Millimeter (mm)

Material : Stainless Steel

Send Inquiry

Send Inquiry