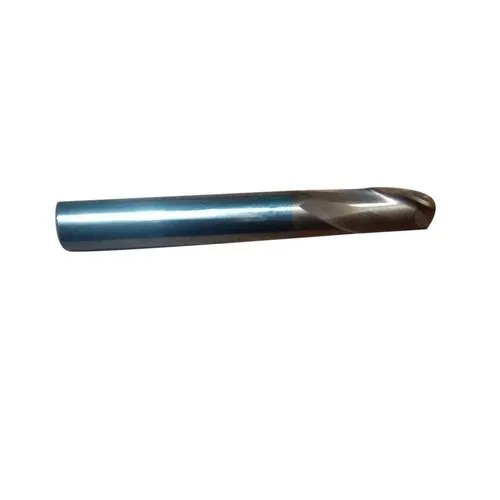

Carbide End Mill Ball Nose Cutter

Price 499 INR/ Piece

MOQ : 50 Pieces

Carbide End Mill Ball Nose Cutter Specification

- Features

- Good Quality

- Coating

- Polished

- Usage

- Industrial

- Operation Type

- Finishing

- Operate Method

- Manual

- Hardness

- 70 HRC

- Shape

- Bar

- Material

- Stainless Steel

- Size

- Standard

- Product Type

- Carbide End Mill Ball Nose Cutter

- Diameter

- 10 Millimeter (mm)

- Color

- Silver

- Length

- 100 Millimeter (mm)

Carbide End Mill Ball Nose Cutter Trade Information

- Minimum Order Quantity

- 50 Pieces

- Supply Ability

- 1000 Pieces Per Month

- Delivery Time

- 7 Days

About Carbide End Mill Ball Nose Cutter

Gain privileged Access to a Crowning piece in cutting technology-the Carbide End Mill Ball Nose Cutter, now offered at a Special Rate with a rarefied Price Cut. This Classic bar-shaped tool, crafted from premium stainless steel, boasts a robust hardness of 70 HRC and measures 100 mm in length and 10 mm in diameter. Designed for industrial usage and manual operation, its polished coating ensures exquisite finishing operations. As a leading supplier and trader in India, we deliver Good Quality guaranteed and Standard size tools for precise performance.

Precision and Versatility for Industrial Applications

The Carbide End Mill Ball Nose Cutter is expertly engineered for specific finishing operations in industrial environments. Used for shaping, profiling, and contouring metals, it excels with manual operation and delivers consistent results. Its bar shape with a polished surface facilitates seamless application on stainless steel materials. This cutter, with a standard size and high hardness, adapts well to precise requirements, making it indispensable for tool rooms, manufacturing units, and maintenance shops.

Reliable Supply and Accessibility Nationwide

We maintain a robust supply ability to ensure seamless availability of the Carbide End Mill Ball Nose Cutter across India's bustling industrial sector. Transport Services cover domestic and export markets, with prompt order fulfillment and sample options for prospective clients. List price transparency and custom quotations support large-volume buyers. Our distribution network guarantees swift access to quality tools, meeting both local needs and overseas demands with reliability and efficiency.

Precision and Versatility for Industrial Applications

The Carbide End Mill Ball Nose Cutter is expertly engineered for specific finishing operations in industrial environments. Used for shaping, profiling, and contouring metals, it excels with manual operation and delivers consistent results. Its bar shape with a polished surface facilitates seamless application on stainless steel materials. This cutter, with a standard size and high hardness, adapts well to precise requirements, making it indispensable for tool rooms, manufacturing units, and maintenance shops.

Reliable Supply and Accessibility Nationwide

We maintain a robust supply ability to ensure seamless availability of the Carbide End Mill Ball Nose Cutter across India's bustling industrial sector. Transport Services cover domestic and export markets, with prompt order fulfillment and sample options for prospective clients. List price transparency and custom quotations support large-volume buyers. Our distribution network guarantees swift access to quality tools, meeting both local needs and overseas demands with reliability and efficiency.

| End Type | Square End |

| Overall Length | 100 mm |

| Length Of Cut | 2 mm |

| Material | Carbide |

| Cutting Diameter(D1) | 10 mm |

| Maximum Cutting Depth | 20 mm |

FAQ's of Carbide End Mill Ball Nose Cutter:

Q: How should the Carbide End Mill Ball Nose Cutter be operated for best results?

A: It is designed for manual operation, allowing users to guide the cutter with precision during finishing tasks to achieve smooth and accurate contours.Q: What are the main applications and industrial uses of this cutter?

A: This cutter is ideal for industrial finishing, profiling, and contouring of metals, particularly where reliable, high-hardness tools are essential for precise shaping.Q: When is sample availability offered for this product?

A: Sample availability is provided upon request, enabling clients to evaluate quality prior to committing to larger orders.Q: Where can this cutter be accessed and delivered within India?

A: It is supplied and traded through a nationwide network, ensuring access and delivery to major industrial regions and tool distributors across India.Q: What is the process for international transport and export of the cutter?

A: Products are dispatched using established transport services meeting international standards, with export packaging and documentation in place for global delivery.Q: How does the polished coating benefit the operation?

A: The polished coating reduces friction, enhances tool longevity, and facilitates smoother finishing on stainless steel surfaces, contributing to overall efficiency.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Ball Nose Cutter Category

10mm Carbide Ball Nose Cutter

Price 80 INR / Piece

Minimum Order Quantity : 100 Pieces

Operation Type : Finishing

Length : 200 Millimeter (mm)

Hardness : Yes

Product Type : Carbide Ball Nose Cutter

300mm Carbide Ball Nose End Mill Cutter

Price 500 INR / Piece

Minimum Order Quantity : 50 Pieces

Operation Type : Finishing

Length : 300 Millimeter (mm)

Hardness : 70 HRC

Product Type : Carbide Ball Nose End Mill Cutter

Send Inquiry

Send Inquiry